Desk Riser

This /woodworking project began as an attempt to declutter my desk and improve my posture. Since my primary computer was an iMac, there was no way to raise the height of the monitor without putting something underneath it. I wanted to take advantage of the vertical space underneath the monitor platform by having a "shelf", and I came up with the idea of a nested design of similar pieces to achieve that.

The idea of a rectangular platform lifted a few inches off the desk sounded incredibly dull (and too easy), so I thought it would be a good opportunity to learn how to cut a dovetail. After an almost month-long detour learning about technique, chisels, saws, and sharpening, I was finally able to cut a clean dovetail in practice material and returned to the project.

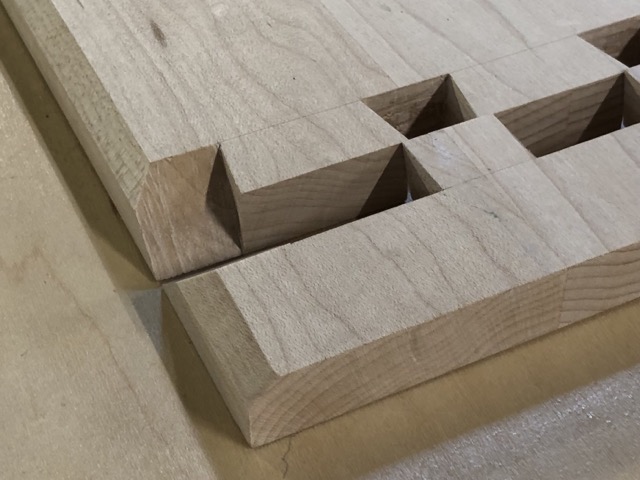

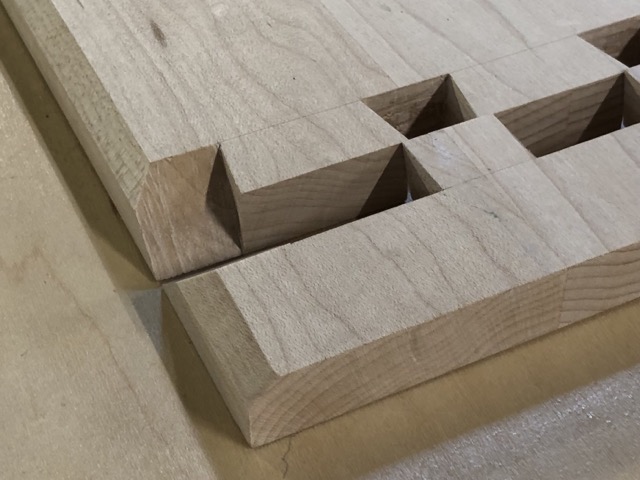

With my approach sorted out, I got back to finalizing the design. I thought it would be nice to add a chamfer on the inner edge so that it caught the light in a way that made the wood look thinner, without actually sacrificing stability. In order to carry a clean chamfer all the way around the bottom lip and the legs, I needed to use a mitered dovetail, where the edges of the board come together at a 45-degree angle instead of the standard way. This added more complexity to my first dovetail project, but really pushed me to maintain precisions and use some chisel guide jigs to make those clean 45-degree corners.

The outer riser was completed first, in April of 2023. I used a few cut-offs of maple in my studio to glue up two roughly 10" wide panels, cut the joinery, and finished with raw hemp oil. The inner riser was started shortly after, but due to the very short legs and the threat of heavy warping if not finished quickly once the legs were cut from the main board, it wasn't until the end of February 2024 that I found the time to sit down and finish the rest of the joinery all in one go. In all, the full piece was completed in early March of 2024.

/desk-riser Stream

March 1, 2024

/stream /woodworking /desk-riser

Today I gave a final high-grit sanding to the desk risers after letting the oil saturate overnight, and another light wipe down of hemp oil.

I'll continue buffing with a rag every day or so while they cure over the next week. Once they're no longer leaving oil on my finger tips, it will be time to take them home.

February 29, 2024

/stream /woodworking /desk-riser

Last night I glued up the dovetail joints on the desk riser, and today I planed (with a chisel) down the protruding pins and then sanded the whole thing to 220 grit, and then 400 grit on the outer surface.

Once sanded, I finished with a generous coat of hemp oil. I didn't let it drink all it wanted, but I did pour the oil directly onto the surface to flood it a bit.

As a relatively "high use" surface, I wanted it to be better protected than a wipe-on application, but I don't think it needed to really drink all the oil it would take.

February 25, 2024

/stream /woodworking /desk-riser

It's been almost a year since I last worked on this desk riser project, since the next step was to cut three long rows of mitered dovetails in relatively quick succession. I finally had the time and focus to sit down for almost an entire day and get through that work, and so now all of the joinery work is complete on this small project. This was completed with my magnetic dovetail guide that I made, and my japanese dovetail saw (a Razorsaw #372).

In addition to the dovetails and the mitered corners, I also cut a chamfer running along the entire "inner" surface of the board so that the visible edge looks thinner than it actually is. On this project I just used a router table, but in the future I hope to get a hand plane to do the job.

One wrinkle is that when doing the test fit, I realized that the smaller "leg" boards of the riser were so short that the end grain orientation made them weak; I split the end grain twice during the test fit process. Next time I'll keep in mind that I probably need a few more inches of board length to use dovetail joinery like this.